20-High Mill

Unmatched Quality for Demanding Materials

At Sendzimir, we’re renowned for our 20-High Mills’ ability to roll rigid materials to very thin gauges without needing multiple anneals. This unique capability produces high-quality surfaces that are challenging to replicate with other mills.

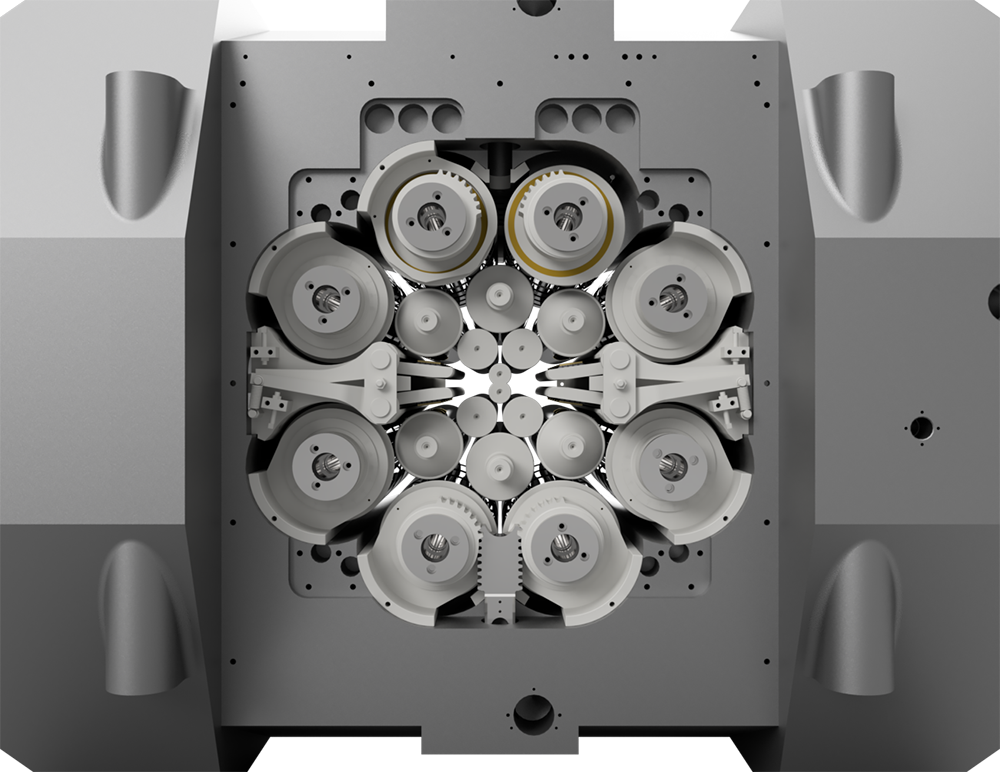

Key Features of Sendzimir's 20-High Mills

Our 20-High Mills are not only efficient but also versatile. They can adapt to varying strip material, width, and thickness, allowing for fast and efficient setup within minutes. Our mills range from handling small-scale operations, rolling a 4” (100 mm) wide strip to below 0.0001” (2.5 microns), to large-scale mills rolling intermediate gauge materials at widths up to 80” (2 meters) at speeds over 3280 Fpm (1000 Mpm).

Our 20-High Mills are designed for superior reductions on hard materials such as stainless steel or titanium. This is possible due to the small size of the work roll, which ensures high specific pressure on a small contact area and enables high total reductions.

While most of our mills are custom-designed to meet specific customer applications, each one shares the core benefits of quality surface, thin gauge capability, gauge tolerance, and shape that Sendzimir’s 20-High Mills offers.

Superior Quality Surface

The Work Roll in our Sendzimir Cluster mill is non-chock-supported, and it can easily be pulled out by hand or by a roll change cart for larger mills. This feature allows for a quick change of the Work Rolls, ensuring the surface quality of the strip reflects the refined polish of a new set of Work Rolls. As a result, most of the world’s 400 series architectural stainless steel is rolled on Sendzimir mills, where the surface finish is paramount.

Exceptional Strip Shape Control

Our 20-high mill design boasts several shape-adjusting capabilities, including lateral movement of the Tapered (opposed) 1st Intermediate Rolls and As-U-Roll control of the secondary crown eccentrics. Combined with our small-diameter work rolls, these features allow for more excellent responsiveness to shape control mechanisms.

Thin Gauge Capacity and Superior Gauge Tolerance

Our 20-High Mills can take higher reductions at thin gauges due to the high specific pressure on a tiny contact area, thus ensuring good strip tolerance across the width of the strip with minimum variation.

Wide Range of Materials Rolled

We can roll any metal our clients need, specializing in tough metals. Whether it’s deep-drawing, low-carbon steels, austenitic, martensitic, and ferritic stainless steels, high-carbon steels for items such as razor blades and saws, or non-ferrous metals such as brass and special alloys of brass, our 20-High Mills can handle it all.

Ready to leverage the precision and quality of our 20-High Mills in your business?

Please fill out the form below. A member of our team will contact you shortly.

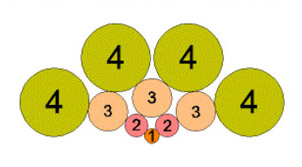

Mill Section Nomenclature Designations

Standard Sendzimir Mill Models

| Mill Section | Nominal Work Roll Diameter | Backing Bearing Diameter | Strip Width Min – Max | Roll Separating Force |

ZR 32 | 0.25” | 1.875” | 4.5 – 8.75” | 5,200 lb/in |

| 6.35 mm | 47.6 mm | 114 – 222 mm | 93 kg/mm | |

ZR 34 | 0.400” | 3.000” | 7.5 – 17.5” | 8,400 lb/in |

| 10 mm | 76.2 mm | 190 – 445 mm | 150 kg/mm | |

ZR 24 | 0.844” | 4.724” | 8.5 – 19.5” | 13,300 lb/in |

| 21.5mm | 120mm | 215 – 500mm | 238 kg/mm | |

ZR 33 | 1.125” | 6.299” | 13 – 37” | 17,700 lb/in |

| 28.5mm | 160mm | 330 – 940mm | 316 kg/mm | |

ZR 25 | 1.260” | 13.23” | 13.8 – 28” | 22,000 lb/in |

| 32mm | 190mm | 350 – 710mm | 393 kg/mm | |

ZR 23 | 1.578” | 8.858” | 19 – 56” | 24,900 lb/in |

| 40mm | 225mm | 480 – 1425mm | 445 kg/mm | |

ZR 22 | 2.125” | 11.811” | 25 – 80” | 33,200 lb/in |

| 54mm | 300mm | 635 – 2030mm | 593 kg/mm | |

ZR 22B | 2.500” | 11.811” | 25 – 80” | 33,200 lb/in |

| 64mm | 300mm | 635 – 2030mm | 593 kg/mm | |

ZR 21B | 3.543” | 16.000” | 36 – 90” | 45,000 lb/in |

| 90mm | 406.4mm | 914 – 2286mm | 804 kg/mm |