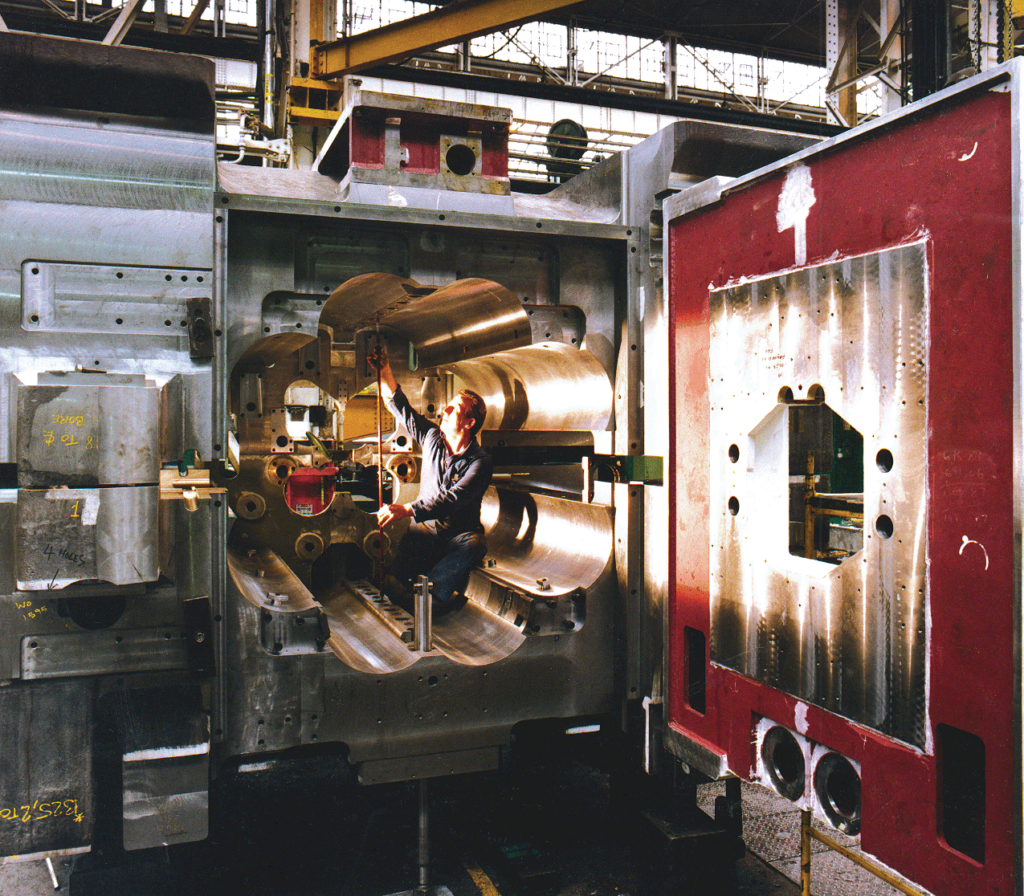

Split Housing

The Power of Split Housing Mill Design

At Sendzimir, we continually strive to innovate, push boundaries, and redefine industry standards. One such example is our unique Split Housing Mill Design. While our Monoblock Housing Mill Design is renowned for its inherent strength and stiffness, our Split Housing Mill Design is equally impressive and offers several unique benefits. This design is especially advantageous for wider strip widths and Silicon Steel Rolling.

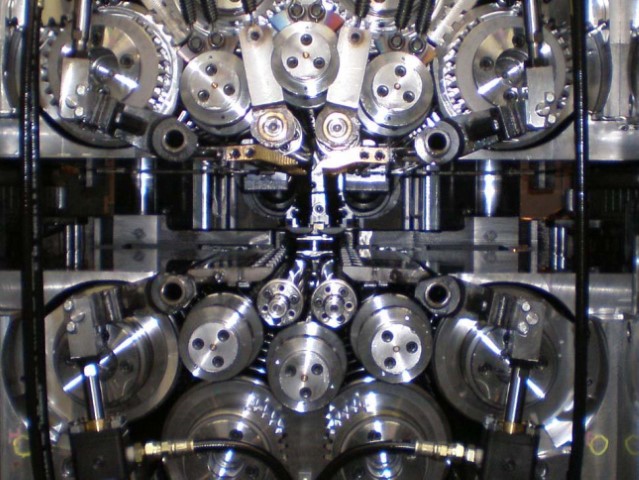

Unparalleled Mill Stiffness

One of the standout benefits of our Split Housing Mill Design is its exceptional mill housing stiffness, or Mill Modules, which measure in metric tons per millimeter stretch. The stiffer a mill is, the tighter the gauge tolerance and the flatter the strip shape. This makes it easier for mill operators to control both parameters during the rolling process.

Although our Monoblock housing has the strongest mill modules for a ZR 21 mill, at 496 MTons/mm, the Sendzimir Split Housing Design approximates that stiffness. It’s the ideal choice for projects requiring strength and wider strip widths.

Innovative Pre-Stressing Technique

Our Split Housing Design stands out in the industry with a unique feature: the two housing halves are pre-stressed together before rolling to a number higher than the maximum RSF (Roll Separating Force). As a result, the housing behaves like a monoblock housing for all practical purposes.

This design offers the flexibility to open the mill housing for roll changes, strip wreck clearing, or other purposes. Furthermore, housing spacers can be added between the two halves to accommodate a slightly larger work roll. We can also place load cells between the housing halves to calculate an actual RSF.

Avoiding the Pitfalls of Common Split Housing Mill Designs

In recent years, various competitors have tried to offer customers a split housing mill in a 4-high housing, assuming it would provide convenience, as the split housing could be easily separated vertically for clearing strip wrecks using the upper or lower screw-down cylinders. Unfortunately, this design comes with a significantly lower overall mill modulus, losing the significant advantages of the Sendzimir design. Not only does the resulting design become unnecessarily complicated, but it also becomes more prone to maintenance issues over time. At Sendzimir, we avoid these complications and focus on creating simpler, more streamlined designs that maximize mill strength.

Are you ready to harness the power of our Split Housing Mill Design?

Please fill out the form below. A member of our team will contact you shortly.