Z-High® Mills - Cold Reversing

Merging Innovation with Efficiency for High-Performance Rolling

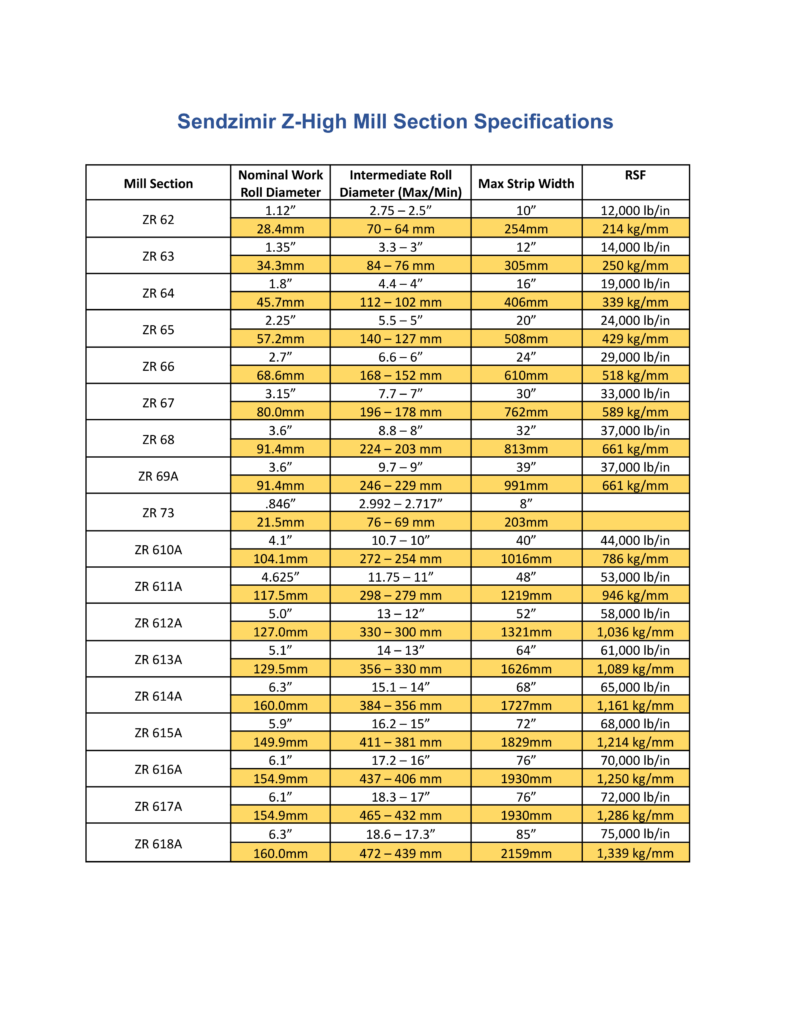

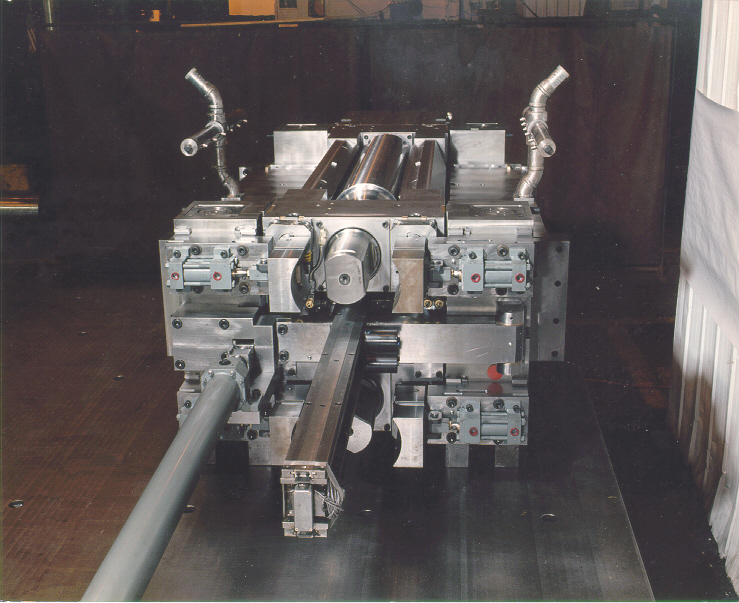

The Sendzimir Reversing Cold Z-High® Mill is a unique blend of cutting-edge Z-High® technology and the traditional concept of reversing cold rolling mills. It embodies the revolutionary attributes of the 20-High cluster mill and the cost-effectiveness of a 4-High mill, making it particularly suitable for rolling high-performance products with stringent specifications in thickness, strength, or gauge accuracy. This makes Reversing Cold Z-High® Mills an ideal choice for manufacturing close tolerance steel strip.

The Superiority of Reversing Cold Z-High® Mills

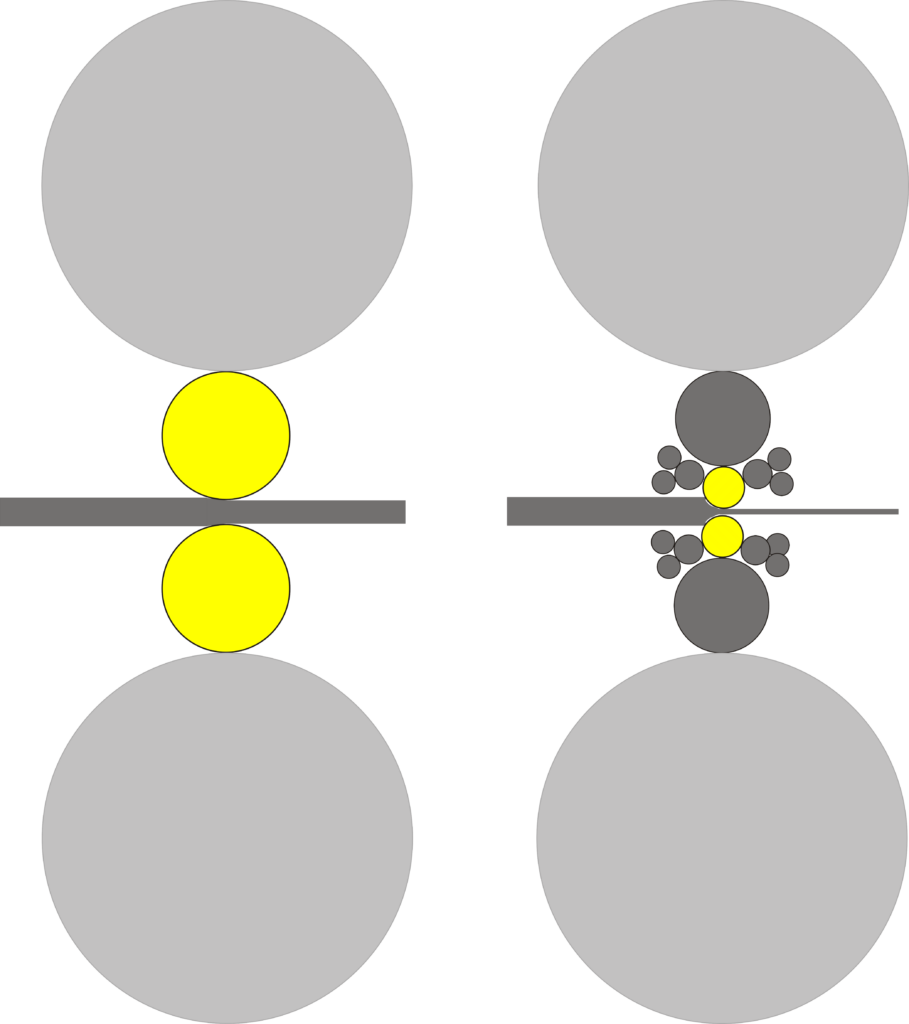

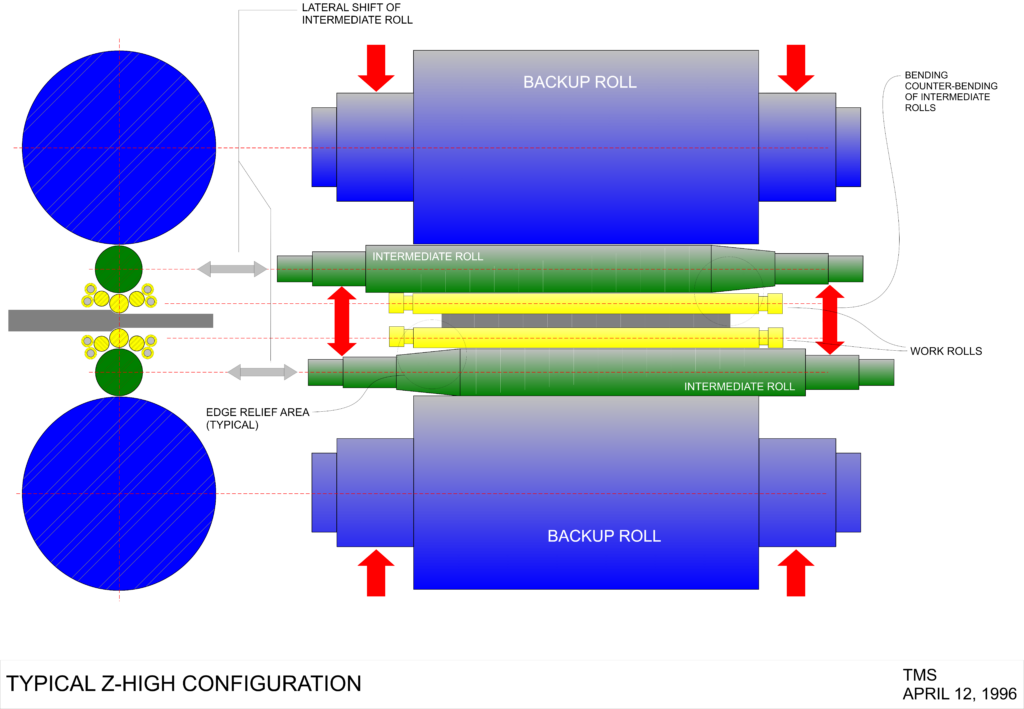

The essence of the Reversing Cold Z-High® Mill is its ability to produce superior strip quality. This is made possible through small work rolls not supported by chocks but rather lateral side support rolls, eliminating lateral flexure. Moreover, the mill’s small work roll diameter reduces roll separating forces, leading to less deflection in the mill structure. This, in turn, drastically reduces the “mill spring” variation, which occurs when the incoming strip gauge changes. The result is inherently less variation in strip gauge and profile.

Our Reversing Cold Z-High® Mills are equipped with roll bending and axial shifting controls, pioneered and perfected by Sendzimir over half a century ago. These features ensure exceptional shape controllability.

The Reversing Cold Z-High® Mill boasts outstanding operational flexibility. It can roll various materials, gauges, and widths without necessitating roll changes. Even when the work rolls need to be changed, the process typically takes less than two minutes. Furthermore, the small rolls can be quickly cycled through the roll grinding process, saving our customers valuable time.

Finally, this innovative design enables the Reversing Cold Z-High® Mill to achieve greater reductions per pass and roll thinner gauges. It can roll harder materials without intermediate anneals and produces a superior surface.

Sendzimir Reversing Cold Z-High® Mill for Aluminium

While Sendzimir mills are traditionally associated with the superior cold rolling of hard-to-roll materials such as stainless steel, our unique technology can also be profitably applied to hard aluminum alloys, such as those containing 3 to 5 percent magnesium. A specific version of the Sendzimir Reversing Cold Z-High® Mill has been optimized for aluminum rolling by incorporating slightly larger work rolls. This modification allows for greater draft reductions, overcoming the common challenge of aluminum breakdown.

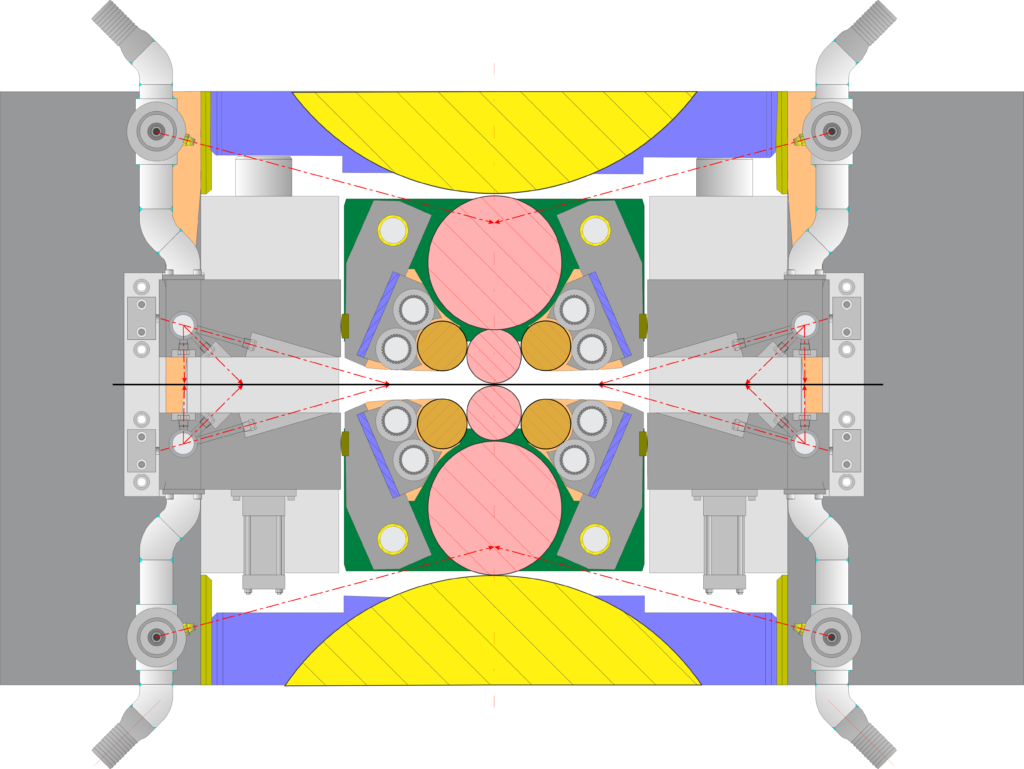

Reversing Cold Z-High® Mill Installation Configurations

There are five major installation configurations for the Reversing Cold Z-High® Mill:

- Retrofitted into an existing 4-High mill and reconverted back into a 4-High by withdrawing the Z-High® Insert and replacing the 4-High work rolls, chocks, and drive spindles within 20 minutes.

- Conversion of a 4-High mill to a dedicated Reversing Cold Z-High® Mill, with the option to widen the mill simultaneously.

- New Reversing Cold Z-High® Mill with smaller diameter backup rolls, chocks, and mill housings.

- New Reversing Cold Z-High® / 4-High convertible mill.

- Tandem mill either in a process line or a stand-alone single-pass tandem mill configuration.

The versatile installation configurations of a Reversing Cold Z-High® Mill result in a smaller capital investment than other alternatives.

Experience the superior quality and performance of our Reversing Cold Z-High® Mills

Please fill the form below. A member of our team will contact you shortly