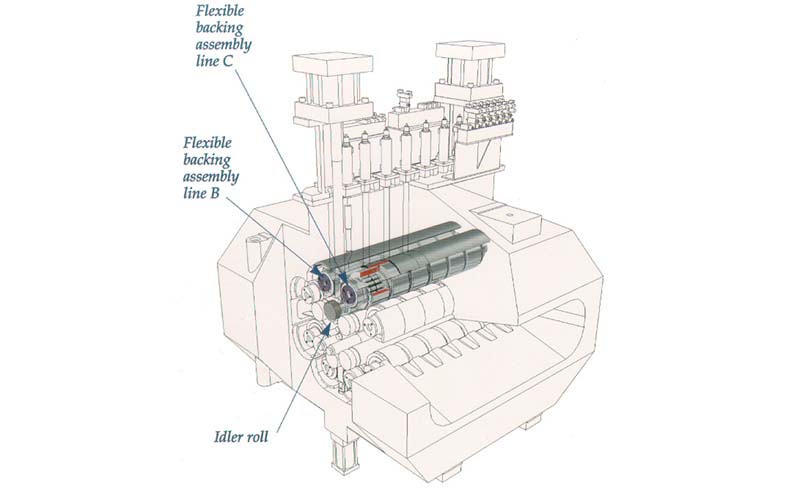

Flex Backing Assemblies

Introducing Sendzimir's Innovative Flex Backing Assemblies

At Sendzimir, we are committed to pushing the boundaries of innovation, so we have developed our unique Flex Backing Assemblies. These assemblies are designed to offer a significantly higher degree of shape adjustment than conventional solid shaft backing assemblies.

Unique Design Advantages

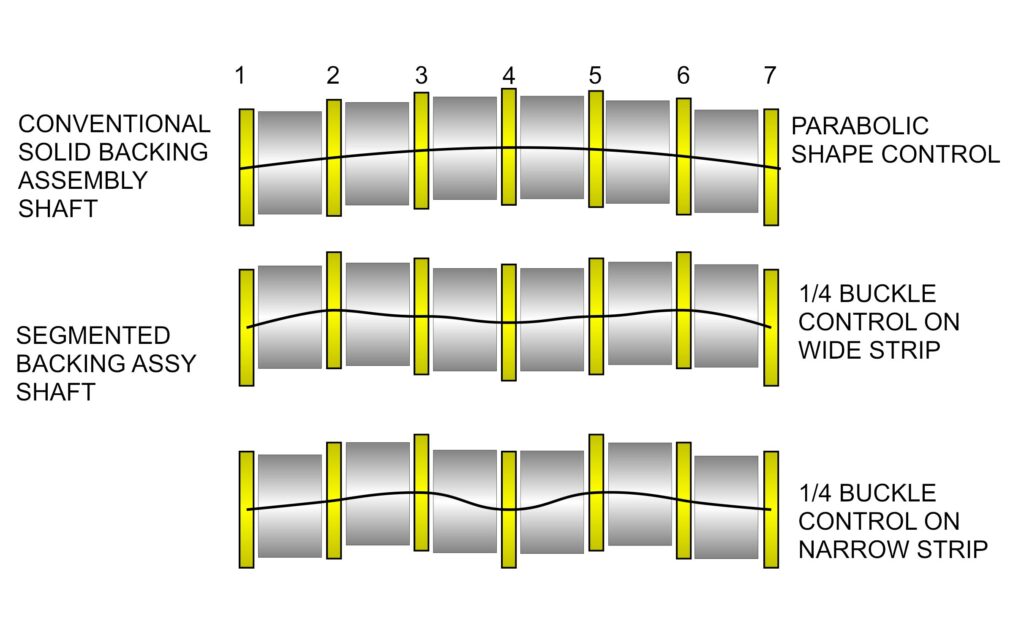

Our Flexible Shaft Backing Assemblies’ design allows for an exceptional offset between adjacent saddles. This unique design capability enables the mill to dial in first, second, third, and fourth-order shape control.

Thanks to our innovative technology, Sendzimir mills can be set up for both the “M” and “W” shapes, providing superior shape control during the manufacturing process. Furthermore, the flexible shaft backing assemblies can move the shape towards the center or closer to the edge of the strip, allowing variable wave amplitude and the period of the mill. This showcases their incredible range of production capabilities!

In addition, the segmented design allows for a combination of quarter buckle control and wedge offset.

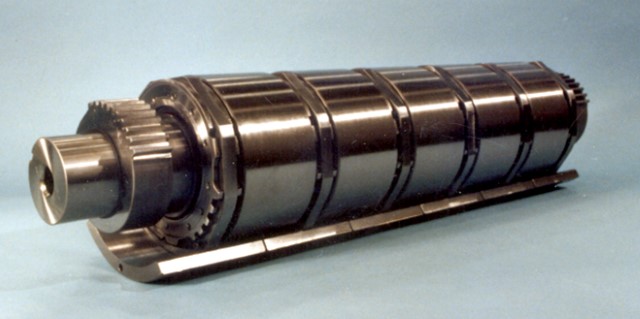

Our Flex Backing assemblies are manufactured to the same standards as conventional backing assemblies. Although the manufacturing process differs, these assemblies can deliver the same strength and durability as their traditional counterparts.

Worldwide Recognition

Our commitment to shape control has set a new standard in the small work roll mill industry. This is why we have a growing customer base in Europe, Asia, and Japan who rely on our flexible shaft backing assemblies. No other supplier of cluster mills outside of the T. Sendzimir, Inc. family can guarantee the degree of shape control capability that comes with our standard-setting backing assemblies.

Flexible Options for Your Needs

Our Segmented Backing Assemblies are designed to be torsionally rigid, yet they can also bend dramatically at each saddle position. Replacing conventional backing assemblies with our flexible shaft backing design significantly improves theoretical flatness adjustability by reducing stiffness. Our backing assemblies increase transverse flexibility compared to traditional designs and enable the crown profile, set by the shape of the backing shafts, to be transferred to the roll gap with minimal attenuation due to intermediate roll rigidity.

Discover the difference that Flex Backing Assemblies can make in your manufacturing process.

Please fill out the form below. A member of our team will contact you shortly.