In the world of metallurgy and advanced material processing, achieving precision and quality is non-negotiable, particularly when working with hard-to-shape materials like stainless steel, titanium, and specialized alloys. These materials demand advanced rolling technology that offers high accuracy, tight tolerances, and consistent performance. Sendzimir’s 20-High Mill technology has established itself as a leader in this domain, leveraging the power of cluster mill technology to deliver unparalleled results.

This article explores how Sendzimir’s 20-High Mill excels in precision rolling and why it’s the preferred choice for manufacturers dealing with complex materials.

What is a 20-High Mill?

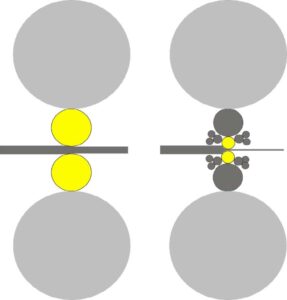

The 20-High Mill, commonly known as a cluster mill, is an advanced rolling mill configuration designed for processing difficult-to-shape materials. Unlike traditional mills that use only two or four rolls, the 20-High Mill utilizes a unique cluster arrangement consisting of:

- One work roll (the roll in direct contact with the material).

- Backup rolls and intermediate rolls that surround the work roll to provide enhanced stability and support.

This innovative setup allows the mill to apply higher pressure while maintaining precise control over material thickness, surface quality, and flatness.

Advantages of Sendzimir’s 20-High Mill Technology

Sendzimir’s 20-High Mill incorporates decades of engineering innovation, making it a go-to solution for rolling high-strength, corrosion-resistant materials. Below are the key advantages:

1. Unmatched Precision Rolling

Sendzimir’s 20-High Mill offers exceptional precision rolling capabilities, with the ability to achieve thickness tolerances as tight as ±0.001 mm. This is particularly critical for applications in industries like aerospace, medical devices, and electronics, where even minor deviations can compromise product performance.

The cluster mill’s design ensures minimal deflection of the work roll, which translates to uniform material thickness across the entire width.

2. Superior Surface Quality

The 20-High Mill achieves exceptional surface finishes by distributing rolling forces across multiple backup and intermediate rolls. This reduces the risk of surface defects, such as scratches, dents, or uneven textures, which are common when rolling hard-to-shape materials like stainless steel or titanium.

3. Capability to Handle Specialized Alloys

Specialized alloys like Inconel, Monel, and titanium-based materials are notoriously difficult to roll due to their high strength and low ductility. Sendzimir’s technology provides the robust force needed to shape these materials without compromising quality. The adjustable roll pressure and precise control mechanisms allow manufacturers to work with a wide variety of materials, including high-performance alloys used in extreme environments.

4. Compact Design with High Efficiency

Despite its complexity, the 20-High Mill is designed to be compact, making it suitable for facilities with space constraints. Its innovative roll arrangement maximizes efficiency by allowing the processing of thinner gauges and wider materials without requiring multiple passes.

5. Enhanced Flatness Control

Flatness is a critical factor in precision rolling. Sendzimir’s mills incorporate advanced flatness control systems that allow operators to fine-tune the rolling process in real-time. This ensures that the final product meets exact specifications, even for materials with challenging dimensional requirements.

Applications of Sendzimir’s 20-High Mill Technology

1. Stainless Steel Rolling

Stainless steel is widely used across industries for its corrosion resistance and strength. However, its work-hardening properties make it challenging to roll. The 20-High Mill provides the force and control needed to roll stainless steel into ultra-thin gauges while maintaining excellent surface quality.

2. Titanium Processing

Titanium’s high strength-to-weight ratio and corrosion resistance make it indispensable in aerospace, medical, and marine applications. Sendzimir’s mills excel in rolling titanium into thin sheets or foils, ensuring consistent quality for demanding applications like aircraft components and surgical instruments.

3. Specialized Alloys

High-performance alloys like Hastelloy, Inconel, and Monel require precision processing to achieve the desired mechanical and chemical properties. The 20-High Mill’s cluster mill technology enables manufacturers to produce these materials with the required tolerances and finishes, even for critical industries like energy and defense.

Key Features of Sendzimir’s 20-High Mill

1. Compact Roll Arrangement

The cluster design uses smaller work rolls surrounded by intermediate and backup rolls, enabling high-pressure rolling while minimizing work roll deflection.

2. High Rolling Force

The mill’s ability to apply intense pressure is critical for processing hard-to-shape materials. This ensures that even high-strength alloys can be rolled into the desired thicknesses.

3. Real-Time Monitoring

Sendzimir’s mills come equipped with advanced sensors and monitoring systems, providing operators with real-time data on material thickness, flatness, and surface quality. This enhances productivity while reducing waste.

4. Durable Roll Materials

The work rolls in Sendzimir mills are made from durable, high-strength materials that withstand the intense forces and temperatures associated with precision rolling. This ensures longevity and consistent performance over time.

Cluster Mill Technology: The Backbone of 20-High Mills

The term cluster mill technology refers to the multi-roll configuration that gives the 20-High Mill its unique capabilities. By using multiple rolls to support the work roll, this technology minimizes deflection, ensures even pressure distribution, and allows for tighter tolerances compared to traditional mills.

The innovative roll arrangement also reduces the stress on individual rolls, enhancing durability and minimizing maintenance requirements.

Industry Impact and Sustainability

The efficiency and precision of Sendzimir’s 20-High Mill technology contribute to reducing material waste and energy consumption—an essential factor for manufacturers aiming to adopt sustainable practices. By enabling the production of thinner, lighter, and stronger materials, Sendzimir mills help industries achieve performance goals while reducing environmental impact.

Conclusion

Sendzimir’s 20-High Mill technology represents a leap forward in precision rolling for hard-to-shape materials. Its ability to handle stainless steel, titanium, and specialized alloys with unmatched accuracy, surface quality, and flatness makes it an indispensable tool for industries demanding high-performance materials. By leveraging the power of cluster mill technology, manufacturers can push the boundaries of what’s possible in material processing, ensuring that the toughest materials meet the most stringent specifications.

For businesses seeking superior rolling solutions, Sendzimir’s 20-High Mill stands as a benchmark of engineering excellence, combining innovation with practicality to meet modern manufacturing challenges.