Classroom Training

Classroom Training for Mill Operators

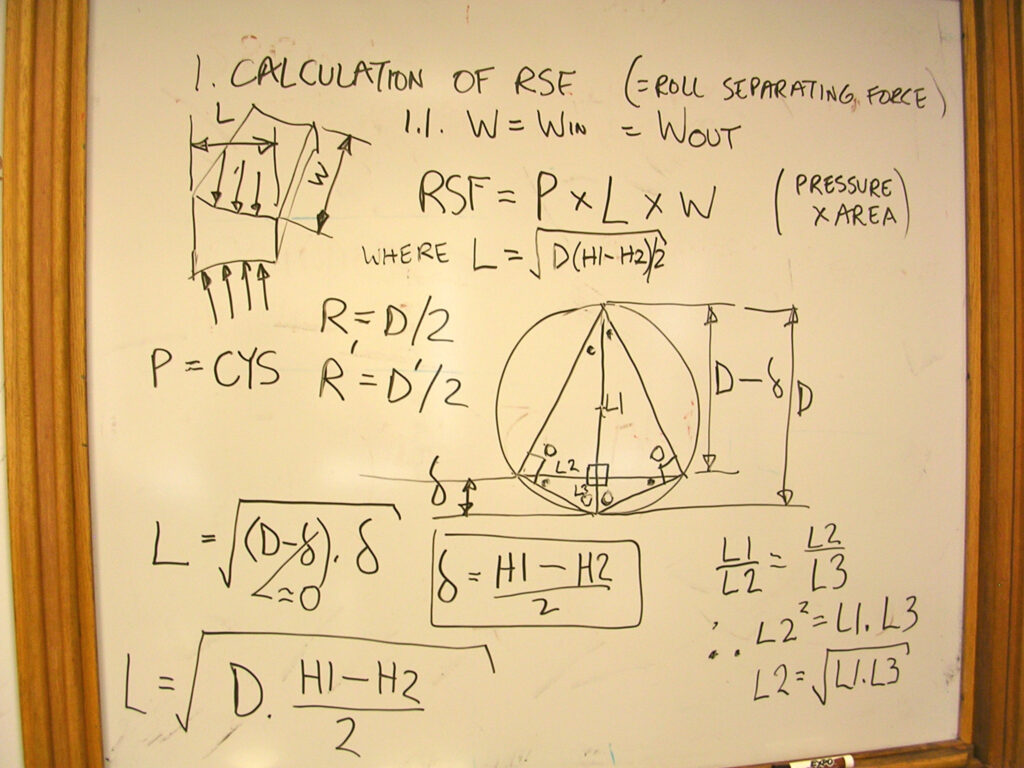

In addition to our practical on-site operational training, Sendzimir offers an in-depth classroom training course that delves into the theoretical aspects of mill rolling practices. This comprehensive program benefits both new and seasoned mill operators, enhancing their understanding of the mill they operate.

Distinguishing Mill Operators from Mill Rollers

At Sendzimir, we recognize the crucial distinction between a mill operator and a mill roller. While mill operators know which buttons to push during the rolling process and have a basic understanding of mill operation, mill rollers possess a more profound understanding of their machinery. They not only know which buttons to push but are also equipped to determine the optimal mill setup to achieve the best strip shape and maximize production. Sendzimir places high value on mill rollers as they are the central figures in efficient and effective operations. Through our comprehensive training programs, we can transform any mill operator into a mill roller.

Customized Training to Meet Your Needs

Depending on your level of experience, our classroom training can be tailored to meet your needs. It can serve as a comprehensive course for beginners, focus on specific problem areas, act as a refresher for those seeking to update their skills or elevate the operation of a mill to new performance heights. Our training is designed for foremen, operators, helpers, and roll-grinding operators involved in mill operations.

Our team of engineers at T. Sendzimir, Inc. are experts in these areas and frequently travel globally, assisting operators and associated personnel in enhancing their efficacy and efficiency.

Preventative Maintenance Training

In addition to our exceptional classroom training services, Sendzimir also offers preventative maintenance training for all of our mills. Given that these units are pivotal to seamless manufacturing operations, their upkeep is of utmost importance. Our preventative maintenance training ensures your workforce is well-equipped to maintain these machines in excellent working condition. This results in fewer repair issues, reduced production downtime, and, ultimately, lower maintenance costs!

Equip your team with the knowledge and skills to become efficient mill rollers and maintain your machinery at its peak performance.

Please fill out the form below. A member of our team will contact you shortly.