ZH Skinpass Mill

A Blend of Efficiency, Advanced Control, and Quick-Change Capability

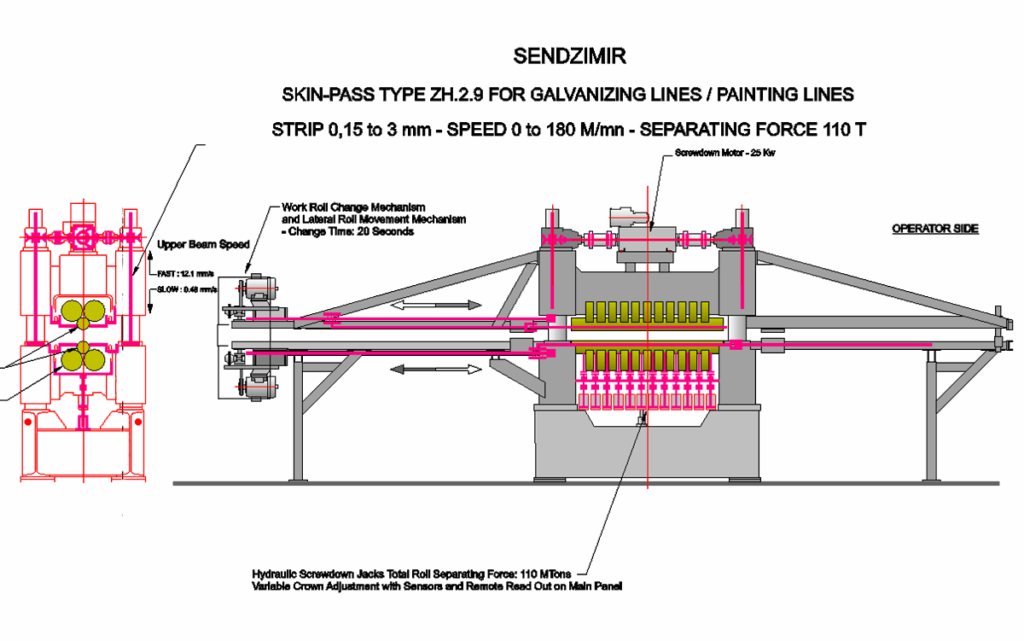

Sendzimir’s ZH Skinpass Mills is a unique blend of cost efficiency, advanced shape control, and quick-change work roll capability designed to integrate seamlessly with galvanizing lines. With over a dozen mills manufactured and operated, T. Sendzimir, Inc. boasts invaluable, field-tested experience. Originally crafted to smooth out the spangles in hot-dipped galvanized steel as a pull-thru mill in line with the galvanizing line, ZH Skinpass Mills have proven their reliability and effectiveness.

Innovative Design

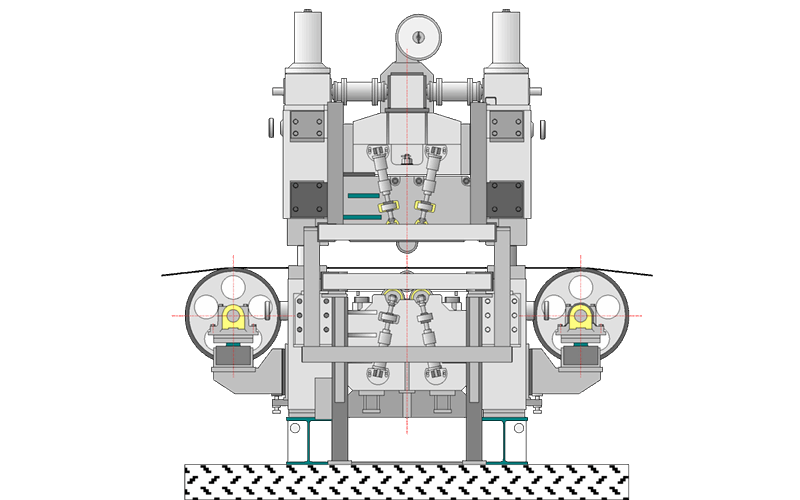

Our Skinpass Mill design is an original concept that incorporates a lower and upper beam into a mechanically operated screw-down system for effortless roll gap adjustment. This design supports a roll stack cluster similar to our classic 12-high mill design, ensuring consistent performance. The backing assemblies of a typical ZH Skinpass Mill are fitted with 10 to 15 bearings in-line, depending on strip width. The work rolls are non-chock supported, non-motorized, and fully supported by their backing assemblies along their entire length.

Quick Work Roll Change

Our ZH Skinpass Mills offer the distinct advantage of quick work roll changes, facilitating seamless production and enhanced efficiency. This feature underlines our commitment to improving equipment productivity and optimizing manufacturing processes.

High Efficiency and Quality

ZH Skinpass Mill users and institutes like IRSID have found no variation in the transfer of roll surface roughness based on roll diameter. The mill’s working pressure remains the only significant factor affecting this transfer. Like our standard 20-high cluster mills, this Skinpass Mill utilizes a small work roll concept to enable high-contact pressure along a small working area. This design reduces the mill’s overall size and strength compared to a conventional 2-High or 4-High of the same width range.

Additional Benefits of Sendzimir ZH Skinpass Mills

- Superior Strip Surface Quality: Small work rolls yield superior strip surface quality and meet grinding machine requirements.

- Adjustability: The continuously variable work roll crown can be adjusted during line operations, with a corresponding display of crown settings. A single line operator can perform Work Roll change in seconds.

- Design Simplicity: The entire ZH Skinpass Mill is light enough to be mounted on a platform above the floor line and integrated into a process line configuration as needed. No heavy cranes or robots are necessary for roll changes, simplifying the incorporation into your operational systems.

Whether you’re working with temper pass rolling, removing spangles from galvanized steel in a process line, or correcting the final strip shape, our ZH Skinpass Mill is an excellent choice.

Ready to enhance your production process with our ZH Skinpass Mills?

Please fill out the form below. A member of our team will contact you shortly.