Planetary Mill

The Evolution and Resurgence of the Planetary Mill

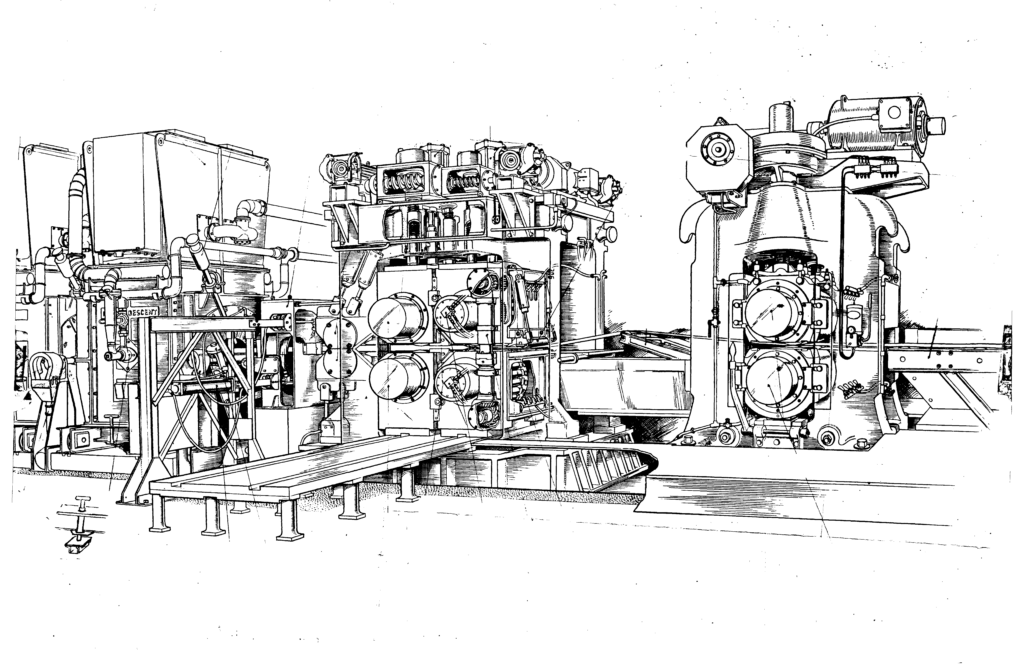

Sendzimir’s 29th patent in 1954 was the Planetary Mill, a machine that was technically ahead of its time. Initially, it catered to clients, producing around a million tons annually. As production scales shifted towards hot tandem mills producing upwards of 5 million tons annually, the Planetary Mill’s advantage seemed to wane. However, with the recent emergence of mini-mills and corporates steering away from thin slab casting, the Planetary Mill has become an effective solution.

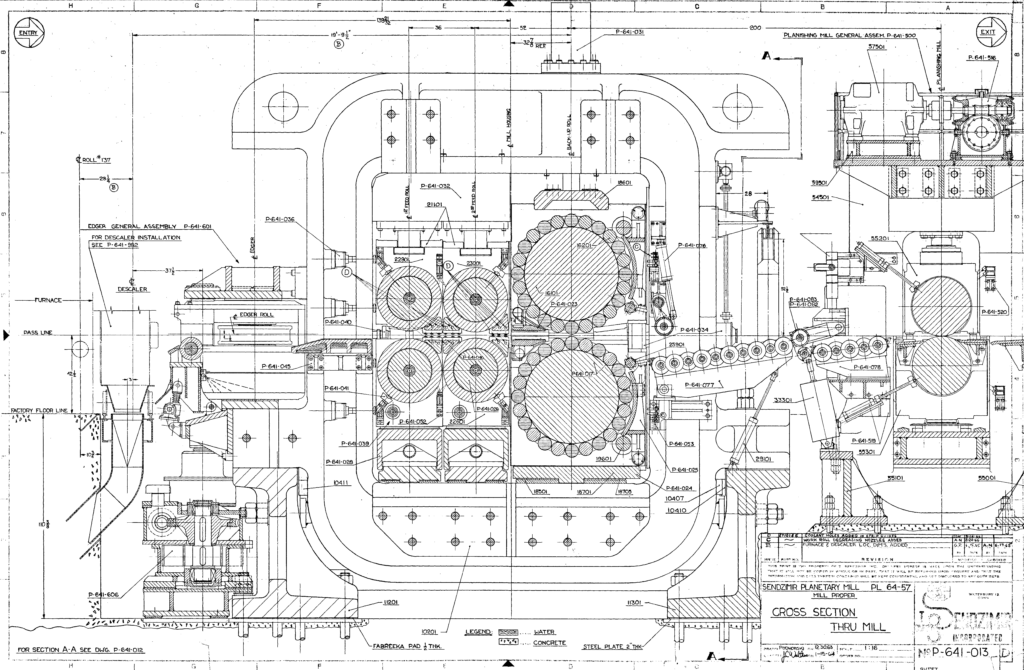

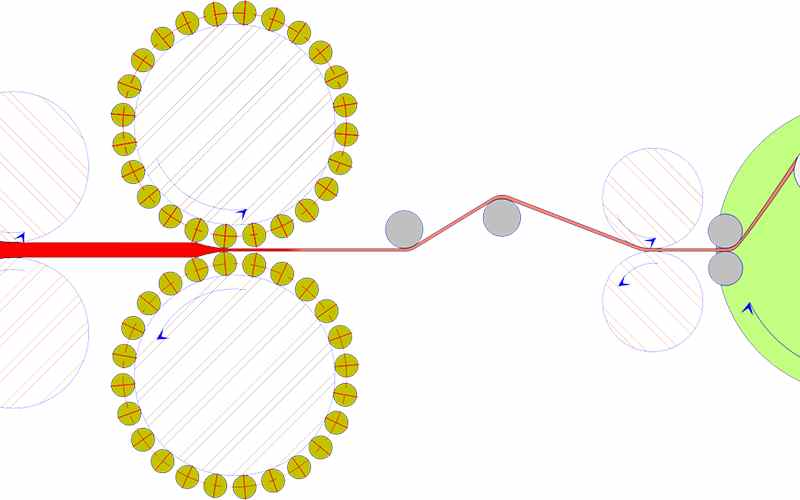

Unique Design Structure

The Planetary Mill’s name reflects its distinctive design. The term “planetary” refers to the arrangement of the rolls around the periphery of each backing roll, with multiple working rolls positioned as satellites. This design borrows crucial elements from the cold 20-high mill, explicitly using a small working roll with a high specific pressure capable of reducing more than a larger 4-high Work Roll. The Planetary Mill can achieve up to a 97% reduction on a hot slab in a single pass.

The arrangement of the rolls provides structural rigidity to the small-diameter work rolls, allowing for very high reductions in a relatively small machine size. This leads to unparalleled efficiency and precision.

Cost-Effective and Compact

Over 26 Sendzimir Planetary mills have been manufactured and used globally. Our mill design offers two main advantages: lower costs compared to a tandem hot mill line-up and a compact design. We strive to provide innovative, affordable solutions for our customers.

We balance cost efficiency with quality and reliability. With Sendzimir, your investment is not a gamble but a strategic move towards enhanced productivity.

Harness the power of innovative technology and elevate your manufacturing process.

Please fill out the form below. A member of our team will contact you shortly.