Wiping Systems

Innovative Wiping Systems by Sendzimir, Inc.

Pollastrelli Wipers were originally developed as a retrofit using undersized old work rolls. Since then, Sendzimir has supplied numerous wipers with new mill installations and we’ve designed custom applications for high-speed, thin gauges, and semi-automated removal systems.

A Closer Look at the Pollastrelli Wiper System

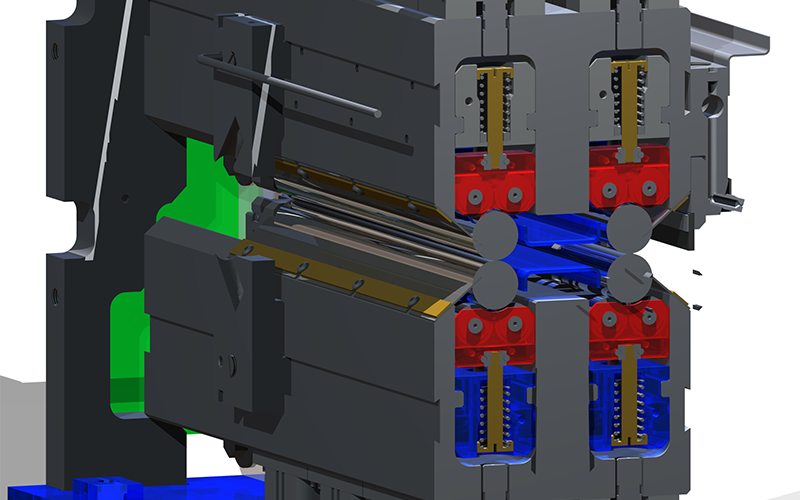

The original Pollastrelli Wiper design consists of a 3-roll wiper with two rolls above the strip and one below. In recent years, however, we have made substantial innovations to the 4-roll wiper design (2 rolls above the strips; 2 rolls below), including new bearing yokes, new spring loading, and variable pressure designs.

Numerous caster bearings support each Pollastrelli Wiper roll across its axial length. This design ensures uniform support across the width, allowing the rolls to conform to the shape of the strip. The entire Pollastrelli wiper assembly is mounted on spring-loaded guides, causing the wiper to “float” and enabling varying passline heights. Wider mills are supported on variable-height hydraulic positioners.

Coolant nozzles are mounted on the upper Pollastrelli wiper assembly toward the mill housing side. They direct the existing coolant back toward the mill housing, forming an effective dam and directing the effluent to the front door and back plates. Air nozzles are supplied for edge blow-offs on narrower mills and are specially designed for low-noise generation.

T. Sendzimir, Inc, also designs:

- Standard 2-Roll 3M roller wipers

- Large Diameter chock supported 3-Roll, Roller Wipers

- Vacuum assist wipers

- Standard hose type wipers

- A proprietary design 2-roll wiper using a small diameter 3M roll as the wiping medium. More information upon request!

- Multiple wiper configuration assemblies of any of the above.

- Specialty 3-Roll designs for high speed/thin gauge applications.

If you have a spare unit, then we can make these changes to the spare and change out each unit until a complete redesign has been achieved on all Pollastrelli wiper units. Please call for more information.

The Pollastrelli Wiper Advantage

Cost Efficiency

Compare Pollastrelli Wipers against your current cost of maintaining contact-type wipers. Based on 50” mills, our calculations show that the Pollastrelli wiper system will pay for itself in as little as 12 months of operation. The cost of operation after this time is limited to re-grinding the rolls every 3 to 6 weeks of operation—based on a 3-shift operation.

Time Efficiency

Our smaller rolls wipe more effectively because they cut through the oil film better than a large-diameter roll. These rolls can also be changed out more easily and re-grounded more cheaply. The Pollastrelli design requires considerably less maintenance and downtime than any other contact wiper, saving you valuable time.

Custom & Compact

Pollastrelli wipers are compact and can be fitted into a smaller space than previous wiper designs. In most cases, they will be an exact replacement for existing hose wiper applications. Sendzimir emphasizes a tailor-made approach, which is why we work to custom-configure Pollastrelli Wipers to your application—for heavy finish gauges, intermediate gauges, and/or very thin gauges.

Thin Gauge Operations

4-Roll Pollastrelli Wipers are available for fragile gauge operations. They are designed to switch from 3-roll to 4-roll operation on-line and during rolling as required.

Scratch Resistance

Unlike various other contact wiper designs, Pollastrelli Wipers will not scratch the surface of the strip. The small diameter rolls have low inertia and, therefore, fast acceleration/deceleration times, which will not skid against the strip’s surface.

Uniformity

Wiper rolls are supported continuously along their length, ensuring uniform wiping action. This, in turn, allows for a consistently milled end product.

Ease of Use

Pollastrelli Wipers assemblies are designed to be easy to maintain and install. These wipers can be supplied with a quick change platform or, depending upon space requirements, can be changed by a porter bar or forklift depending on size (strip width) and application. Use new Super Pollastrelli Wiper Design and Edge Relief for narrow strip rolling, variable wiping pressure across the width of the strip, and the added benefit of easy-to-remove cartridges that are optimal for maintenance processes.

With well over 100 systems in operation worldwide, Sendzimir’s Pollastrelli Wiper System is the equipment best suited for your business!

Please fill out the form below. A member of our team will contact you shortly.