Shapemeter

Revolutionary Shapemeter Technology by Sendzimir

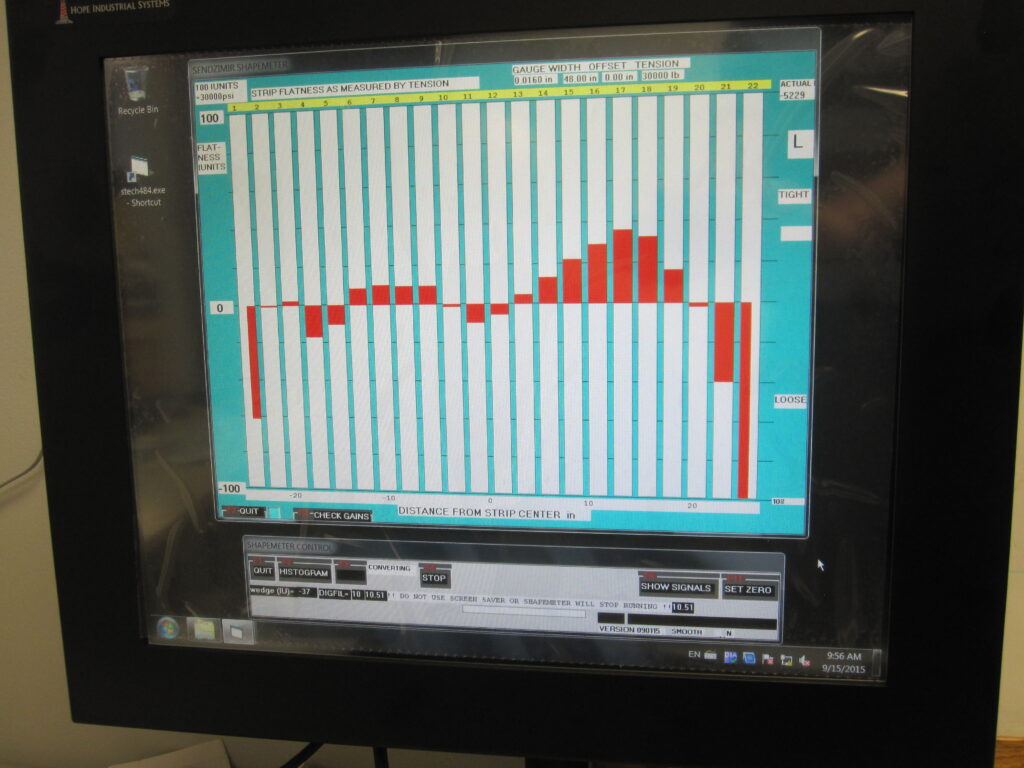

Sendzimir’s Shapemeter is an integral part of our operations. It works with our rolling mills, providing real-time visualization of the strip’s shape during production. Before the Sendzimir Shapemeter, it was impossible to visualize the strip while rolling under tension. However, thanks to Sendzimir’s patented solution, this is a thing of the past. Today, T. Sendzimir, Inc. proudly offers its groundbreaking shapemeter technology.

The Original Shapemeter

The shapemeter’s original design remains as relevant to rolling mill operations today as it was in 1994, which is why Sendzimir continues to offer this field-proven equipment.

How It Works

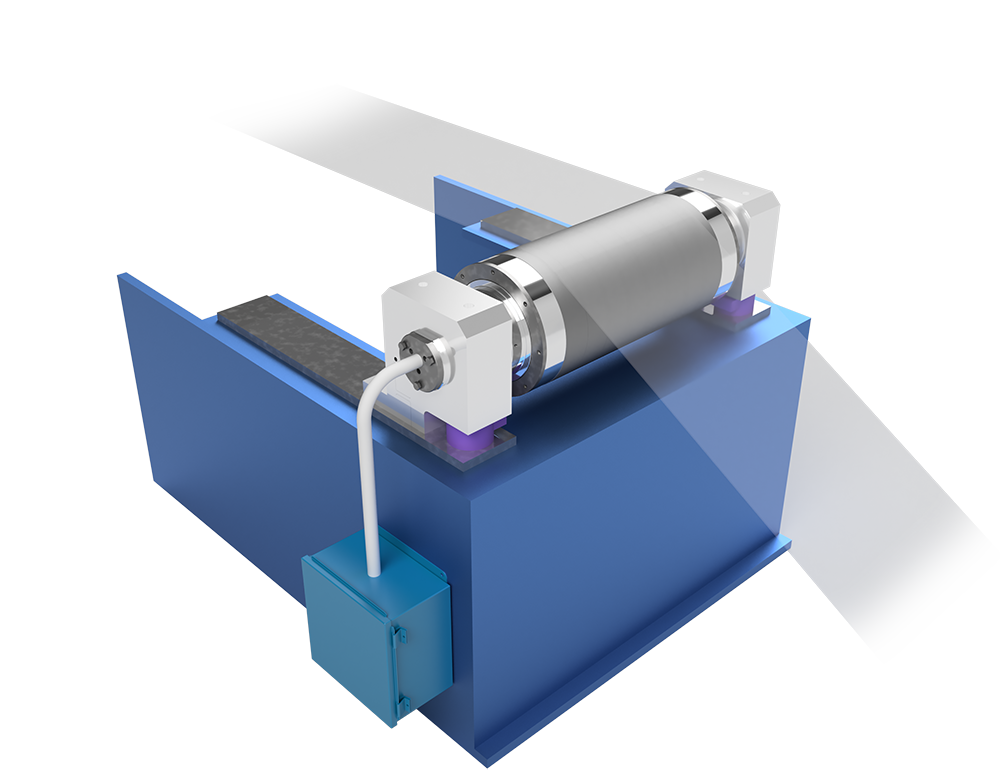

The shapemeter employs a fixed shaft spanning the width of the strip, supported by stationary blocks. A separate bearing is mounted on this shaft at each measuring zone, with a plain or urethane-covered steel ring mounted on the outside of this bearing, covering the full width of the zone.

Inside each bearing, a fixed transducer is mounted within the shaft to measure the radial force on the bearing. The output signal from each transducer is directly wired to a computer or other display device, and the transducers are loaded for the full 360° rotation of the roll.

We offer this shapemeter in two versions:

- Version 1: Used when the unit operates at a fixed wrap angle.

- Version 2: Used when the unit must replace an existing billy roll.

Sendzimir Shapemeter Design

Our newer, low-cost Sendzimir shapemeter has been in service for several years. This compact invention uses a simple design to measure the tension of the strip across its width during rolling. It was initially developed for the narrower strip marketplace (30″ and less).

The Sendzimir shapemeter systems are incredibly compact, self-contained assemblies mounted on the board of the deflector rolls. The simplicity of this design allows T. Sendzimir, Inc. to offer the Sendzimir shapemeter at a highly competitive price.

How It Works

The Sendzimir Shapemeter functions by measuring tension distribution across the width of the strip. The strip passes over the Sendzimir shapemeter sensor roll at a fixed wrap angle, and the radial force generated is measured by load cells mounted beneath the roll.

The system then converts differences between the forces on various measuring zones into tension stress differences, considering the strip’s known width and thickness. The calculated differences are then displayed on a monitor for the user.

Benefits of the Sendzimir Shapemeter

All components of the Sendzimir Shapemeter are very small, enabling units to be fitted into very restricted areas and keeping the weight, inertia, and cost to a minimum. Additionally, Sendzimir Shapemeters uses standard commercial computers and input boards to ensure the greatest possible performance is achieved at minimum cost.

The Sendzimir Shapemeter assemblies are mounted on a retractable frame for quick retraction in an emergency, minimizing the risk of device damage. The units are also equipped with heavy guards for additional protection.

Sendzimir Shapemeter Adaptability

The Sendzimir Shapemeter is adaptable and versatile. In reversing mills, the shapemeter rolls are mounted on the left and right sides of the mill, allowing for flatness readings when rolling in either direction.

Each sensor is a stationary load cell to keep the cost reasonable and avoid complications caused by factors such as slip rings. Each zone is supported by a pair of support rollers mounted on the stationary load cell. This setup allows for an independent measurement of the tension in the strip passing over each segment, along with several other data points, virtually eliminating crosstalk between measuring zones.

Experience the versatility of Sendzimir's Shapemeter firsthand.

Please fill out the form below. A member of our team will contact you shortly.