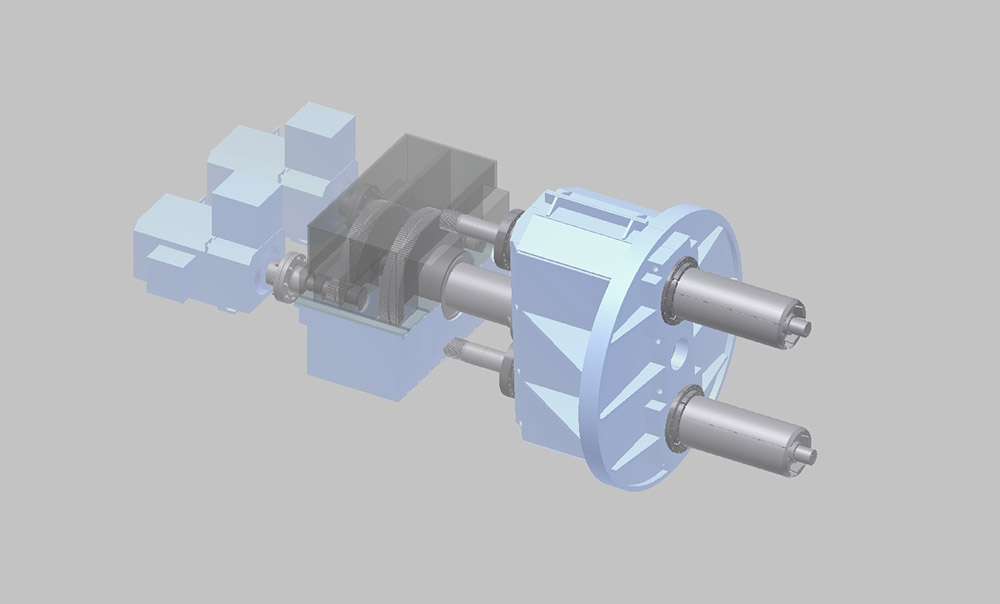

Carousel Coiler

A Unique Solution for Continuous Strip Coiling

The Carousel Coiler, a product of our innovative design approach, is a unique solution for continuous strip material coiling. Initially developed for use with our Planetary Mill, its versatile design has proven effective in various applications, including annealing lines, galvanizing lines, leveling lines, coating lines, pickling lines, and both hot and cold tandem mill installations.

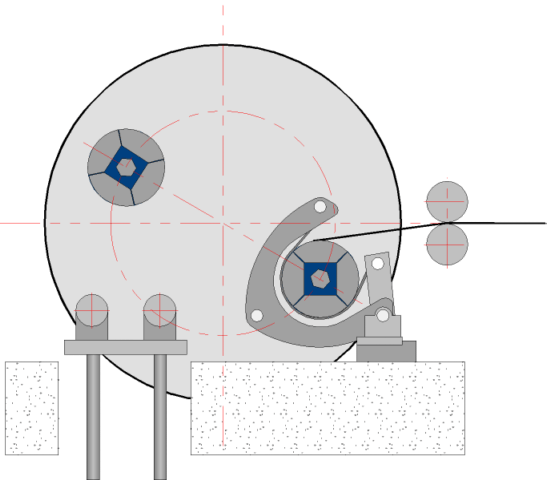

Working Principle

The Carousel Coiler operates on a unique mechanism that enables continuous coiling. Initially, the belt wrapper in the receiving position wraps around the coiling mandrel. As the belt wrapper retracts, the coiling process begins.

Simultaneously, the carousel drum rotates 180 degrees counter-clockwise. This rotation moves an entire coil to the stripping position and positions an empty mandrel to receive the next strip length. After coiling on the full mandrel is completed, power is transferred to the ready empty mandrel. The finished coil is stripped, and the next coiling cycle commences.

Benefits of the Carousel Coiler

Sendzimir’s Carousel Coiler offers a multitude of benefits:

Cost Efficiency

True to Sendzimir’s commitment to delivering cost-effective solutions without compromising quality, the Carousel Coiler promises lower equipment and foundation costs.

Compact Design

The compact design of our Carousel Coiler ensures that it fits into spaces where traditional designs may struggle. Its space-efficient design requires only half the floor space of dual discrete winders and belt wrappers.

Time-Efficiency

Components like the Sendzimir Coil Loader-Stripper and Transport System are integral to the Carousel Coiler, optimizing production efficiency and saving time.

Simplified Operation

The Carousel Coiler utilizes a shared drive for both mandrels, simplifying the production process and enhancing operational ease.

Don't wait! Contact us today and take the first step towards revolutionizing your coiling process with Sendzimir's trusted, industry-leading technology.

Please fill out the form below. A member of our team will contact you shortly.